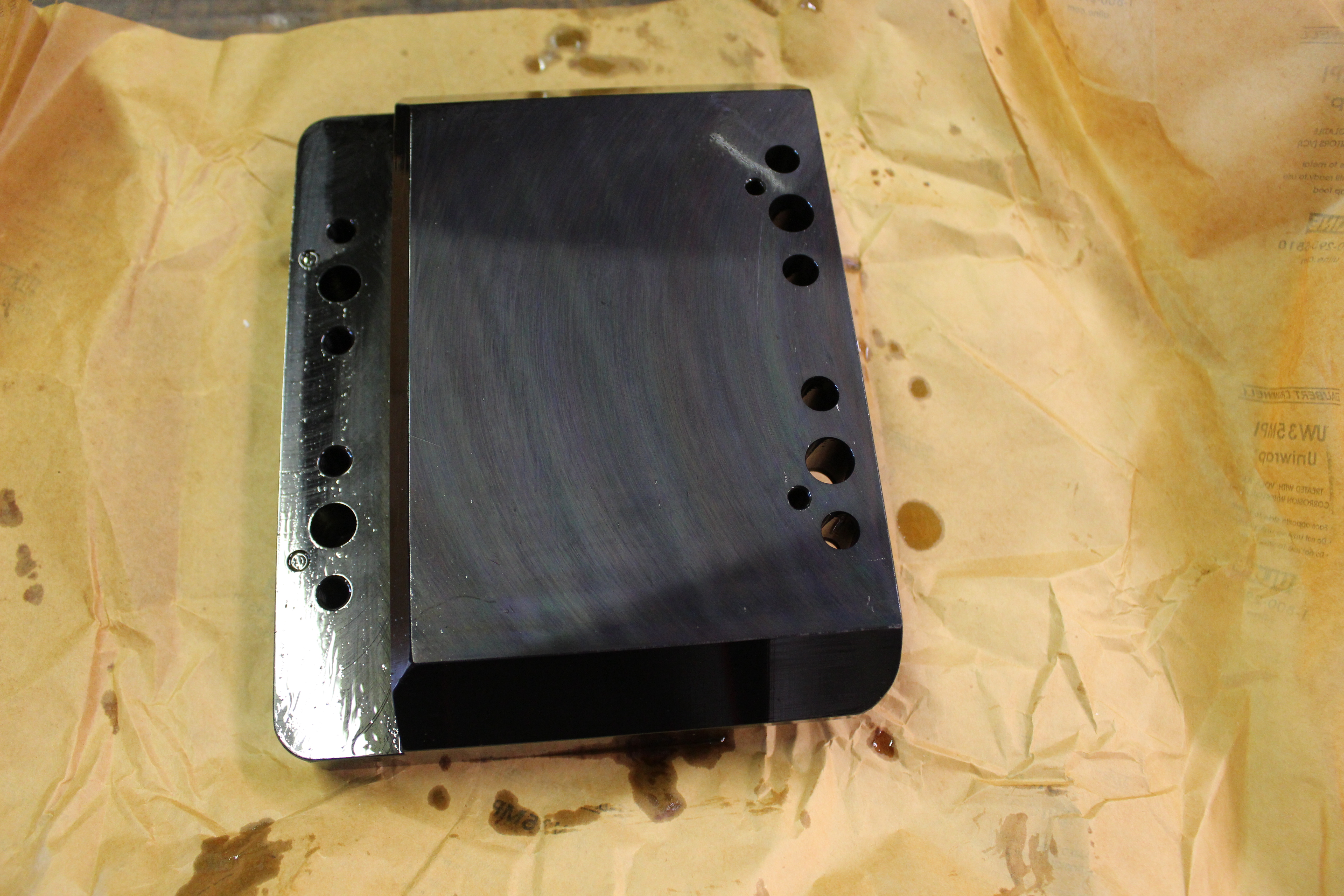

Black Oxide

Blackening or Black Oxide is the process of chemically converting the surface of metal (usually steel) to a black oxide. Oxide is a term for rust, but if formed in the correct conditions will create a structurally patterned form of rust called oxide. The blackening process that we utilize is called a hot process. Which means that our blackening solution temperature is elevated to 285 degrees to accomplish the black oxide process.

Blackening or Black Oxide is the process of chemically converting the surface of metal (usually steel) to a black oxide. Oxide is a term for rust, but if formed in the correct conditions will create a structurally patterned form of rust called oxide. The blackening process that we utilize is called a hot process. Which means that our blackening solution temperature is elevated to 285 degrees to accomplish the black oxide process.

The alternative that many people utilize is called a cold or room temperature blackening process. These can be obtained at many places often times cheaper, but be warned that many of these products will not hold a candle to our hot process and usually you get what you pay for in this case.

Key Benefits

- Excellent finish for parts that will be shelved for later processing

- No dimensional (tolerance) change.

- No extra tolerencing is needed for design when finishing parts with this process.

- The thickness of the coating is only 10's of millionths of an inch thick.

- Very cost effective process.

- Very cost effective process.

- Corrosion protection

- Improved lubricity

- Decorative finish

- Reduced light glare

- Pre-treatment for paint

- Good conductivity retained

- No embrittlement or pitting

- No welding fumes

Certifications

BlackCote uses chemicals that conform to the following specifications and certifications:

- MIL C-13924-Class 1

- MIL HDBK-205A

- AMS-2485

Large Quantiity Processing

Maximum capabilities

- Length - 42" plus or minus depending on part width

- Width - 24" plus or minus depending on part length

- Depth - 24" plus or minus depending on over all size of part due to displacement of solution

Fast quotes

Fax, email, or phone us on what you want to process and we can have a quote back to you asap.